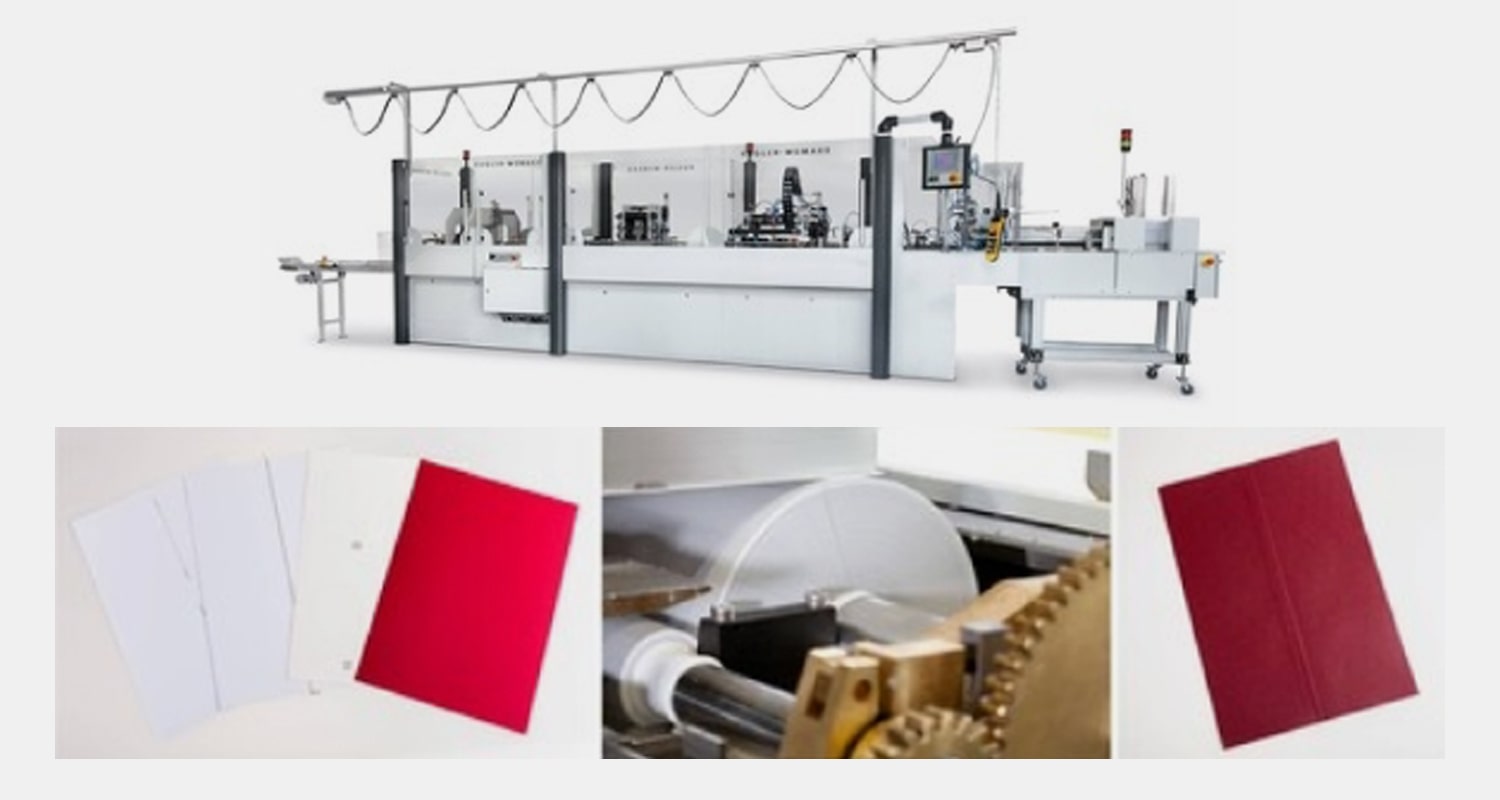

PassPort 2 – Passport machine for laminating of covers and/or chip-inlays

The PassPort 2 machine laminates covers and/or chip-inlays onto layers sewn by PassPort 1. All passport machines by Kugler-Womako adhere to the strict quality guidelines of the ICAO and ISO for “Machine Readable Passports (MRP) and electronic passports.” All styles of passports and e-passports can be manufactured by combing the PassPort 2 with our PassPort 1, 3 and 4 machines.

Passport 2 basic equipment

Add-on options