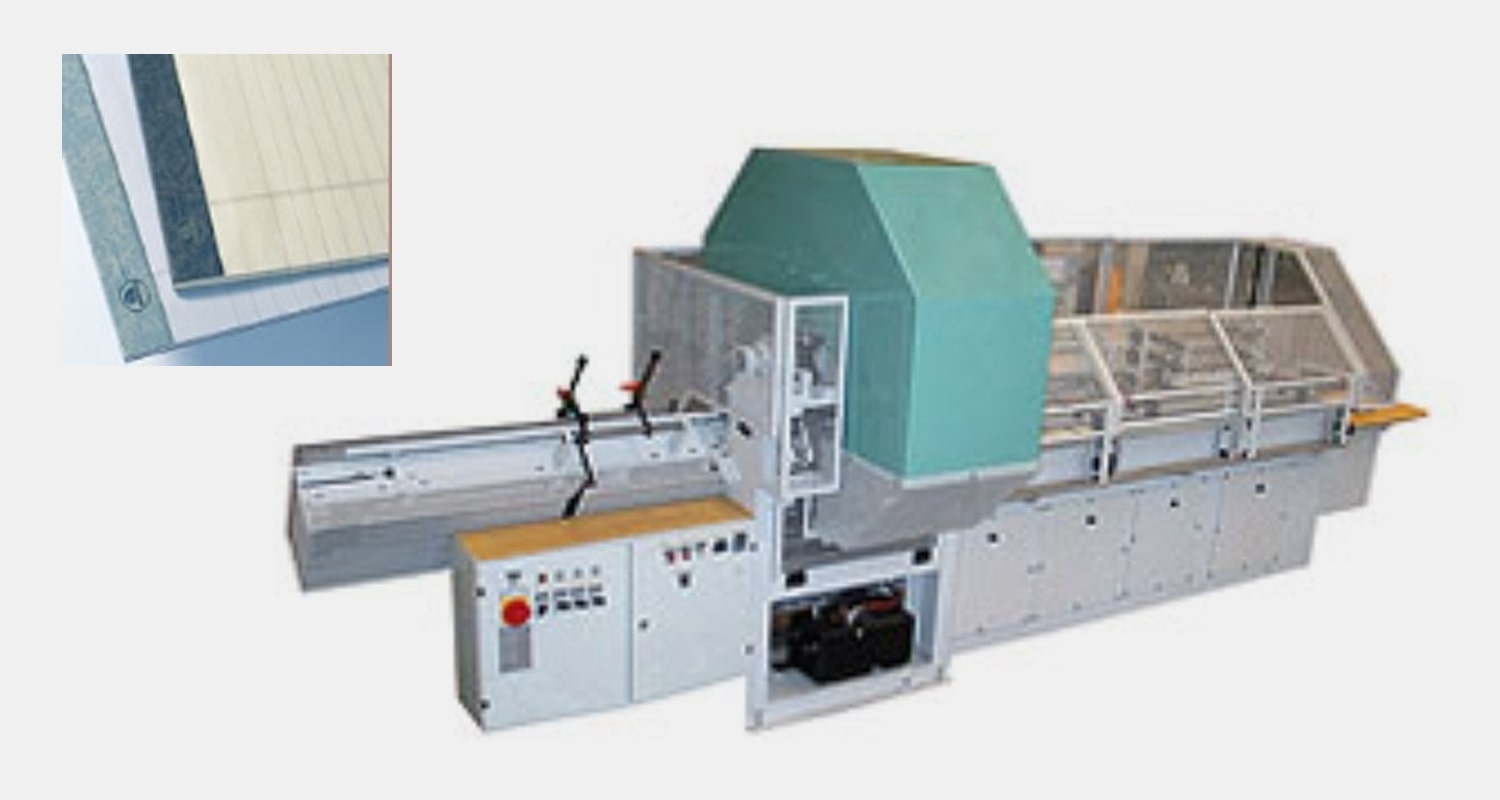

ProPad 317 + 317-20 – Glue binding pad machine

Stationery manufactures, bookbinding companies and trade finishers can produce graphic arts products in small to medium quantities with the glue binding pad machine ProPad 317 and ProPad 317-20.

The production options range from standard products to sophisticated products, with high quality print and materials. The already-cut pads are fed into the machine with or without bottom sheet. The cover sheet is fed via the feeder and is grooved (according to pad size), put on pad and aligned with the pad.

The pads are glued with either cold glue or hotmelt. Subsequently, a glue strip is applied on the back of the bottom sheet, and the cover sheet is flapped over and pressed on. Machine is user-friendly. Sizes can be changed in a few minutes.

ProPad basic equipment