Superflo® Ink Filters & Surge Suppressors

When do you need a filter in printing?

Graymills Superflo® filters are specially designed for flexographic and gravure ink systems, providing effective filtration to eliminate quality problems from contaminants that can also damage costly anilox rolls. Sizes for all printing applications. Filters are available standard (models HFLT/HFST/HFNT) or as surge suppressors (models DDPSFST/DDPSFNT).

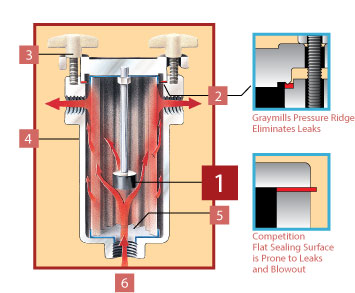

How does a Superflo filter work?

Superflo® ink filters are designed to overcome the typical pressure drop and reduced ink flow due to clogging that occurs with ordinary filters. A permanent magnet (optional rare earth megaMAG available) suspended over the intake port traps ferrous particles which find their way into the ink and diffuses the flow outward into the filter screen flutes. Filtered material is trapped on the inside of the removable/reusable stainless steel filter cartridge.

How do you clean a Superflo filter?

To clean, just remove the cartridge. All contaminants come out with it. Graymills Superflo® filters are self-draining – no wasted ink or messy leftovers.

How do I select the Superflo cartridge I need for my printing application?

Stainless steel filter cartridges are available in four different mesh screens recommended for the following applications:

How do I select the Superflo cartridge I need for my printing application?

Model HFNT/DDPSFNT** For use with narrow web centrifugal pumps, diaphragm pumps 3/8” or smaller or peristaltic pumps.

** For diaphragm and peristaltic pumps, use surge suppressing filters (Model DDPSFNT)

Model HFST/DDPSFST** For use with mid to wide web centrifugal pumps or 1/2” or larger diaphragm pumps.

** For diaphragm and peristaltic pumps, use surge suppressing filters (Models DDPSFT/DDPSFNT)

Model HFLT Double Length Filte